17.01.2023

Within These Applications, You Will Benefit From a Rotary Lobe Pump

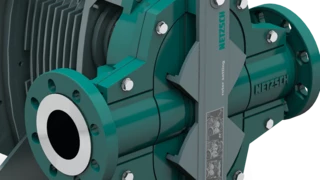

Which application is a rotary lobe pump suitable for? NETZSCH Pumps & Systems has the answer. As a global specialist in complex fluid management, we always find the right pump solution for your application.

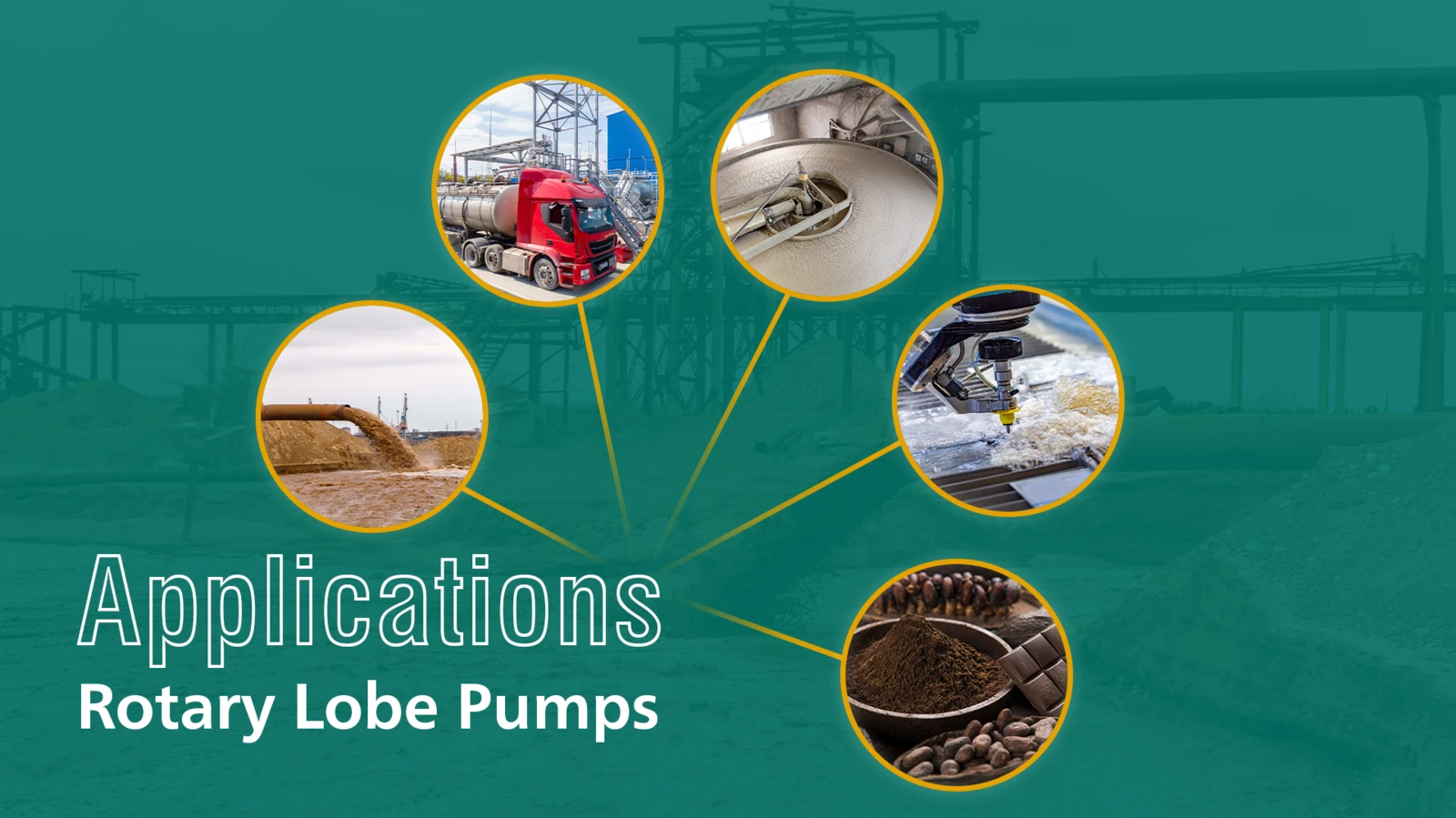

The range of applications for rotary lobe pumps is as diverse as their advantages. We will show you the applications you will particularly benefit from using a rotary lobe pump.

Reduce operating costs by using a rotary lobe pump

Konsultasi Khusus

A conventional application for rotary lobe pumps is wastewater pumping, especially industrial wastewater in treatment. However, this industrial wastewater poses a significant challenge to pumps and systems worldwide. Due to its composition, industrial water is one of the most complex forms of wastewater. Depending on the application, the contents range from dissolved and undissolved, inorganic and organic substances to acidic and basic media, as well as oils and poisons. These partly aggressive components demand everything from the systems and thus lead to increased wear. The focus is on a robust, durable design and high operational reliability. But easy maintenance also plays a significant role. These are the advantages offered by TORNADO® T.Envi® rotary lobe pumps from NETZSCH for water treatment applications. Compared to frequently used centrifugal pumps, you can more than double up the service life by using a rotary lobe pump and thereby sustainably reduce your operating costs. Another possible application in the field of environment & energy is the use of rotary lobe pumps on ships. On board, they are used as bilge pumps to pump out water that collects in the lower part of the ship's hull in case of a leak or during regular operation or to pump wastewater. One of the biggest challenges on boats is the limited space available. Every centimetre used for the engine room comes at the expense of transport space. Despite the small area, the systems must be robust, as hardly any workforce can be assigned for repairs during shipping and stopovers in ports are to be avoided for reasons of time and cost. In addition to the robustness, rotary lobe pumps require significantly less space than progressing cavity pumps. Which makes them the perfect solution for use in confined spaces, such as for bilge and conveying tasks.

Reduce downtimes by using rotary lobe pumps

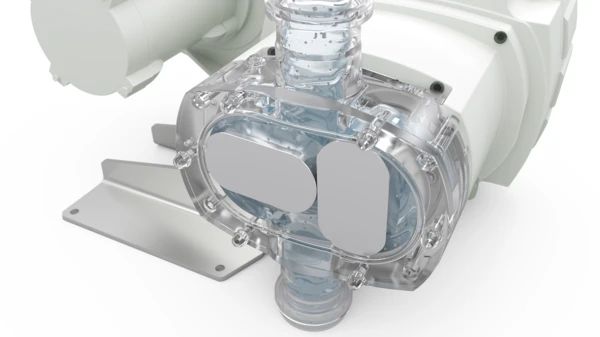

Pumping gold, copper, or molybdenum slurry is a typical mining application for rotary lobe pumps. They all have one thing in common. They are abrasive media that lead to high wear and low service life. You must stop your plant frequently and interrupt the pumping to replace the worn parts. This results in long downtimes and the associated high downtime costs. Therefore, it is even more critical that pumps and systems are particularly robust as well as quick and easy to maintain. Features that are embodied in particular by the TORNADO® T.Envi® rotary lobe pumps. Maintenance is straightforward thanks to the innovative FSIP® (Full Service in Place) design. There is no need for time-consuming disassembly from the pipeline or the drive. This reduces your workload to a minimum and shortens downtimes. One mine operator reduced his service time per operation from ten and a half to two hours. Convert your process to a rotary lobe pump for mining applications and reduce your downtime sustainably.

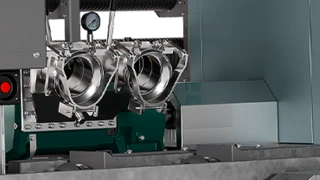

Cara mendapatkan manfaat dari pompa lobus putar yang higienis

Persyaratan untuk pompa lobus putar di area aplikasi makanan & farmasi sama sekali berbeda dengan yang ada di sektor pertambangan, lingkungan & energi. Kondisi utama di sini biasanya adalah pemompaan yang lembut, akurasi pengukuran yang tinggi, dan kepatuhan terhadap standar kebersihan tertinggi. Inilah yang ditawarkan oleh pompa lobus putar semua logam TORNADO® T.Sano®. Berkat penggerak sabuk, pompa ini beroperasi sepenuhnya bebas minyak dan oleh karena itu tidak menimbulkan risiko kontaminasi. Hal ini membuat mereka ideal untuk membawa campuran bahan baku untuk kakao, nougat, dan massa kembang gula lainnya, misalnya. Keuntungan lain yang ditawarkan pompa lobus putar dalam aplikasi makanan adalah mudah dibersihkan. Selain desain FSIP® yang inovatif, yang juga disediakan oleh pompa lobus putar industri, pompa lobus putar TORNADO® T.Sano® dengan desain yang halus meyakinkan dengan pembersihan yang mudah (CIP - "Prosedur Pembersihan di Tempat") dan sterilisasi (SIP - "Sterilisasi di Tempat"). Pembersihan dan sterilisasi pompa dapat dilakukan tanpa melepaskan pompa dari sistem. Hal ini secara signifikan mengurangi waktu henti Anda untuk pekerjaan pembersihan. Selain memenuhi standar kebersihan tertinggi, pompa lobus putar juga menawarkan pemompaan yang lembut dan akurasi pengukuran yang tinggi untuk aplikasi di sektor makanan. Persyaratan ini harus dipenuhi, misalnya, saat memompa anggur bersoda dan semi-sparkling, lemak yang dapat dimakan, dan minyak. Dikembangkan untuk aplikasi yang sangat penting secara higienis, pompa lobus putar dari NETZSCH juga memungkinkan takaran yang tepat. Berkat geometri internal ruang pompa yang dioptimalkan, tidak ada yang menghalangi pemompaan yang lembut dan terus menerus tanpa turbulensi. Selain itu, Anda dapat memberi dosis secara tepat dan dapat direproduksi menggunakan pengaturan kecepatan.

High efficiency with the use of a rotary lobe pump

All these demands on rotary lobe pumps are combined in chemical, pulp & paper applications. Examples include pumping fatty acids, emptying tank trucks, pumping adhesive primers, decanting water in coal fines recovery, or processing paper and pulp. For these applications, the TORNADO® T1-F rotary lobe pump offers exceptionally high flow rates, a large delivery capacity, excellent suction conditions, and compact dimensions. Compared to frequently used centrifugal pumps, rotary lobe pumps provide significantly higher efficiency. This is a decisive advantage, especially with increasingly rising energy costs. NETZSCH also developed the TORNADO® T.Proc® rotary lobe pump, primarily for chemical, pulp and paper industries. This pump offers you the highest level of operational reliability and thus enables compliance with the strictest legal requirements and efficient pumping.

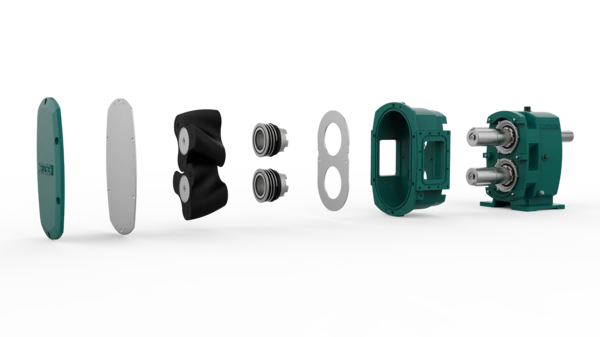

Portofolio pompa lobus putar dari NETZSCH

The areas of applications for rotary lobe pumps are just as diverse as the NETZSCH portfolio. Numerous other uses are covered thanks to six different models, from hygienic applications to wastewater treatment to shipbuilding.

Does your application fit outside the specific fields of a rotary lobe pump? No problem. As a global specialist in complex fluid management, our product portfolio includes numerous other positive displacement pumps, grinders, dosing and barrel emptying systems. No matter what, we will find the optimal solution for your application.