17.02.2025

NETZSCH Highlights NEMO® Progressing Cavity Pumps and PERIPRO™ Peristaltic Pumps for Lithium Battery Manufacturing for the EV- Battery Industry

In the rapidly expanding lithium battery manufacturing sector, precise handling and conveyance of complex fluids is crucial. NETZSCH offers two advanced pumping solutions tailored to meet these demands: NEMO® Progressing Cavity Pumps and PERIPRO™ Peristaltic Hose Pumps.

Customised Consulting

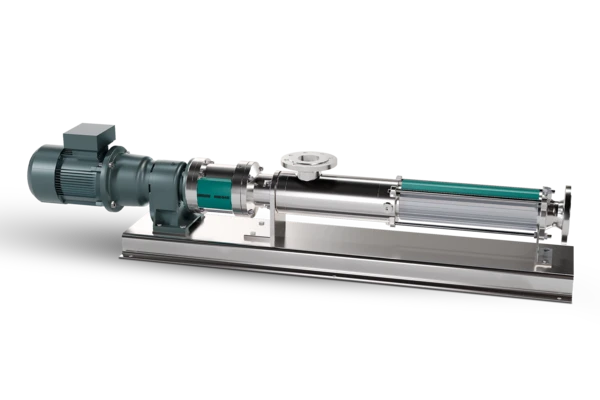

NEMO® Progressing Cavity Pumps: Precision and Reliability

NEMO® Progressing Cavity Pumps are regarded as the industry standard pump technology for battery manufacturing due to their advanced capabilities in handling abrasive slurries and harsh fluids without pulsation. These pumps deliver exceptionally high metering precision, ensuring smooth, steady flow without contamination. This is achieved by a design with no metal-to-metal contact and lubrication-free shaft joint options, which protect against product contamination. With the ability to operate at slow speeds, NEMO® pumps can deliver extremely steady, low flows, essential for the battery production process. The pumps also offer a variety of construction materials, including abrasion-resistant hardened steel, ceramic rotors, and over 30 elastomer options. NETZSCH even formulates its elastomer compounds in-house to ensure optimal resistance to the solvents and chemicals present in battery production.

These pumps excel in demanding applications, particularly electrode coating and slurry mixing. For coating, NEMO® pumps deliver highly viscous slurries with a high concentration of solids in a consistent, pulsation-free manner to the coating system, ensuring thin and uniform coatings. In mixing applications, they accurately meter raw materials, allowing for a perfect mix that supports optimal battery performance. They are also highly effective in metering ceramic slurries, electrolytes, adhesives, resins, and other aggressive battery process fluids.

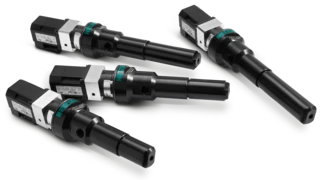

NETZSCH also offers Magnetically Coupled NEMO® Progressing Cavity Pumps: These pumps have a contamination-free design. By using magnetic coupling instead of traditional seals, they ensure zero leakages, making them ideal for handling hazardous fluids like electrolytes and solvents. The absence of metal-to-metal contact prevents contamination, which is critical for high-purity applications in battery production where even minor impurities can compromise battery quality. Moreover, they offer enhanced safety, reduced maintenance needs, and longer operating life, making them both safe and cost-effective in continuous, demanding environments.

PERIPRO™ Peristaltic Pumps: Durability and Efficiency

The PERIPRO™ Peristaltic Pump, another NETZSCH product innovation, is designed for handling complex fluids in demanding battery manufacturing applications. These robust hose pumps feature heavy-duty construction and are equipped with large, easy-to-maintain rollers that enhance service life and deliver up to 30% energy savings. Unlike traditional peristaltic pumps that use shoe technology, PERIPRO™ pumps require 90% less lubricant, adding further operational efficiency.

Their compact, seal-less design prevents hazardous emissions, making them safe and environmentally friendly. The pump hoses are available in a variety of elastomeric materials, offering excellent chemical resistance and making them suitable for abrasive, corrosive, viscous, and delicate products—ideal for applications like electrolyte injection, slurry transfer, and mixing aggressive chemicals.

NETZSCH Comprehensive Solution for Battery Manufacturing

Together, NETZSCH’s NEMO® Progressing Cavity Pumps and PERIPRO™ Peristaltic Pumps provide unmatched precision, reliability, and efficiency in lithium battery manufacturing. These pumps not only support the quality and consistency needed for battery performance but also ensure safe, contamination-free operation across various production stages.

With NETZSCH’s dedication to innovation and quality, they are the trusted partner in advancing India’s battery production capabilities and meeting the global demand for sustainable energy solutions.