NETZSCHicon

Dry Running Protector

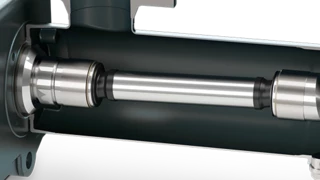

In the context of pumps, a dry running protector refers to a protective device or system installed to ensure that the pump is not operated without sufficient liquid supply.

When a pump runs dry, it means that there is little or no liquid in the fluid being pumped, which can harm the pump. Dry running can lead to overheating, wear and damage to the pump. The dry running protector fulfils several essential functions:

- Damage prevention: It protects the pump from damage by stopping operation when there is too little liquid to cool and lubricate it.

- Energy efficiency: The protection saves energy by preventing the pump from running unnecessarily when little or no liquid is pumped.

- Extension of service life: Avoiding dry-running situations extends the pump's service life by minimising wear and damage.

There are various methods of implementing the dry running protector. This can be done, for example, by coupling inserts of pressure sensors, level sensors or flow sensors. When the sensor detects that the liquid level is too low or that there is no flow, it stops the pump or switches it to protection mode to prevent damage. This is especially important in applications where pumps perform critical tasks, such as water supply, chemical industry or heating and cooling systems.