17.04.2024

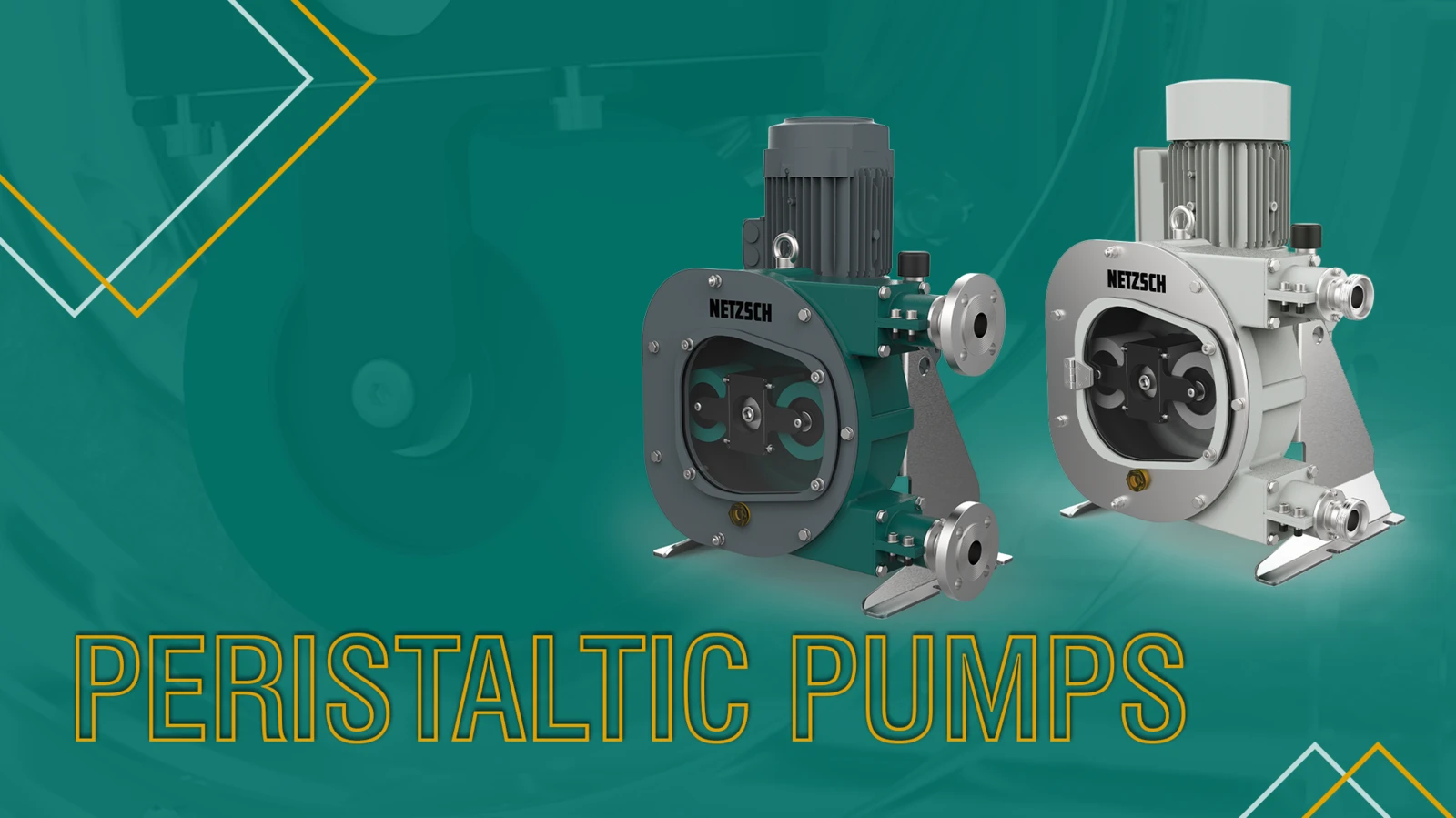

NETZSCH PERIPRO® Peristaltic Hose Pumps Sustainable Performance for Excellent Process Reliability

Are you looking for an optimal peristaltic pump for conveying and dosing operations?

NETZSCH Pumps & Systems India, a global specialist in handling complex media, manufactures progressing cavity pumps, rotary lobe pumps, multi-screw pumps, grinding, dosing, barrel emptying systems, and peristaltic hose pumps.

Robust, reliable, and consistent: This is precisely what PERIPRO® peristaltic pumps from NETZSCH is well known for.

Read below to understand why you can rely on NETZSCH's robust technology when buying a peristaltic pump and its benefits.

Customised Consulting

Robust construction: Benefits with choosing a peristaltic hose pump

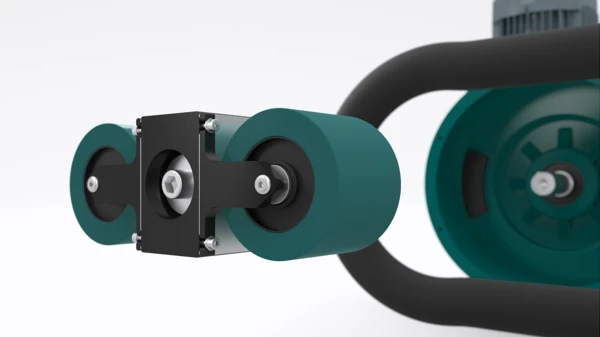

The robust design of the PERIPRO® peristaltic pumps from NETZSCH, comes with large rollers and hard bearings that guarantee durability and reliability even under the most demanding operating conditions. The design of the rollers has the best balance to create a vacuum at suction and hold the pressures at the discharge end with minimal impact on the life of the hose.

The seal/valve-less construction ensures no risk of leakage, which is a significant advantage when handling corrosive, or expensive fluids. They also offer higher energy efficiency due to reduced friction and the elimination of seal-related energy losses. The pump design therefore requires the lowest amount of lubrication fluids.

Additionally, they are specially designed to operate continuously in challenging environments where they have to withstand high temperatures, abrasive and corrosive media, or high operating pressures. Installing a peristaltic pump is a good investment in durability. The wearing part, hose, and materials are engineered to maximize service life and minimize maintenance requirements.

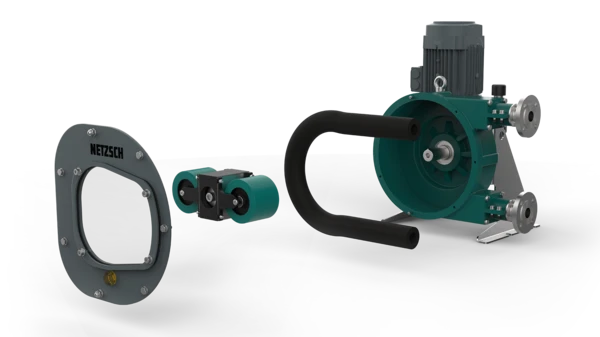

This reduces operating costs and ensures constant, efficient, and reliable pumping performance. The robust design also makes maintenance easier and enables wearing parts to be replaced quickly with its openable front cover design, which significantly reduces downtime and increases process reliability at the same time. By choosing a peristaltic pump from NETZSCH, you benefit from maximum operational reliability and efficiency.

Due to its robust design, the hose pump is ideally suited for pumping materials with up to 70 percent solids and fiber content.

NETZSCH Peristaltic pump with just one wearing part, hose!

The innovative design of PERIPRO® peristaltic pumps, which is characterized by a minimum number of wearing parts, significantly reduces maintenance work and unplanned downtime. This pump has no valves or mechanical seals. The only wearing part is the hose. The hose is produced with a unique manufacturing process, the inner layer is extruded with high-density textile reinforcement and a precisely machined outer layer. Thanks to controlled tolerances, the hose ensures optimal compression and fast installation/replacement.

In addition, the ease of maintenance of our peristaltic pumps with openable front cover, allows you to carry out maintenance/hose replacement work without special tools or extensive expertise. This reduces your maintenance costs and increases productivity at the same time. The peristaltic pump requires less than 90 percent lubricant than conventional pumps available in the market. By choosing a PERIPRO® peristaltic pump from NETZSCH, you are investing in a solution that offers high efficiency and simple, user-friendly maintenance.

Applications: The Benefits of choosing a NETZSCH PERIPRO® Peristaltic Pump

PERIPRO® peristaltic pump from NETZSCH offers various advantages, particularly in handling complex media in demanding industrial applications. These pumps are characterized by their versatility and reliability in conveying efficiently and dosing accurately.

In the food and beverage industry, peristaltic pumps offer gentle and hygienic transfer of sensitive media such as juices, sauces, tomato ketchup, oil-based seasonings, and dairy products. The Clean In Place enabled design with an openable front cover ensures the removal of the rollers and hose with ease and provides crevice-free pumping with the highest product quality and operational safety, making compliance with the hygiene regulations.

The Pump design allows for excellent flow control and hence is well suited to dosing applications. In chemical, Ceramics, and industrial applications, peristaltic pumps excel in dosing aggressive, viscous, or abrasive media with precision and safety. This capability makes them ideal for processes requiring accuracy and material resistance. Furthermore, peristaltic pumps offer exceptional efficiency and reliability in dosing flocculants, reagents, chemicals, or pumping sludge in wastewater/effluent treatment plants.

They can handle media with a high solids content of up to 70 percent with ease. In mining, and mineral beneficiation, Viscous, abrasive, and solids-containing media can be optimally pumped, and doses corrosive chemicals, reagents, polymers, and additives accurately with its innovative design and capability to resist the media characteristics.

Choosing a peristaltic pump from NETZSCH ensures performance, adaptability to specific requirements, process reliability, and long service life.

How to reduce maintenance costs with peristaltic pump?

Choose NETZSCH PERIPRO® peristaltic pump and reduce maintenance costs: The robust and service-friendly design allows you to conduct routine inspections and replacements quickly and efficiently, minimizing downtime. The longevity of the components, combined with the ability to replace wearing parts (hose) without specialized tools or external service teams, also contributes to low lifecycle costs.

Applications

Few wearing parts

Robust construction

CIP capability: Buying an easy-to-clean peristaltic pump

PERIPRO® peristaltic pump from NETZSCH comes with Clean In Place (CIP)-capability, the process owners can simplify and optimize the cleaning processes in the production. Peristaltic pumps are designed to enable thorough and efficient cleaning without removing them from the system. This saves time and reduces the risk of contamination, thus, ensuring a high level of process reliability.

The FDA-certified hose and sanitary tri-clamp connections comply with the hygiene standards, especially for the food, pharmaceutical, and cosmetics industries. With peristaltic pumps, benefit from low downtime, long service life of the pump, and simultaneously, the safety and quality of your products. This saves time, reduces operational costs, and increases overall productivity.

With its innovative design, the PERIPRO® hose pump in the food version enables contamination-free conveying as well as a simple cleaning process.

Buying a peristaltic pump and benefiting from dosing accuracy

PERIPRO® peristaltic pump technology from NETZSCH guarantees high dosing accuracy, which is crucial for numerous applications requiring precise metering of liquids, such as in chemical processing, wastewater treatment industry, or food production. These pumps maintain consistent and accurate dosing even under varying pressure conditions and across a wide delivery range, which ensures consistent end-product quality, and optimizes the use of valuable resources and thus reliable production.

Extremely high suction power with peristaltic pump

Choosing a PERIPRO® peristaltic pump provides the benefit of high suction capability, which is vital for efficient and reliable pumping. This makes it a self-priming pump. This feature allows the effective suction and transfer of highly viscous, abrasive, or sensitive media without compromising the integrity of the product.

The ability to create a strong vacuum also facilitates the suction of liquids from deep tanks or through long suction lines, greatly enhancing the pump's versatility. A peristaltic pump is a robust and dependable solution that significantly boosts process efficiency due to its exceptional suction capacity.

What NETZSCH PERIPRO® Peristaltic Pump offers you

Whether industrial, chemical or food, you can choose the respective peristaltic pump variant from NETZSCH, your global partner in handling complex media. Together with you, we will find the model optimized for you and your application. We promise you Proven Excellence – outstanding performance in all areas.

As customer satisfaction is our top priority, our service does not end with delivery of the peristaltic pump. We offer comprehensive aftermarket service support that includes advice, maintenance, spare parts, and repairing and modernizing your pump.

Brochure