Upstream oil-gas-water mixtures

Progressing Cavity Pump Systems - Artificial Lift Method for Upstream Oil Production

Optimizing Oil & Gas Upstream Operations with Advanced Pump Technology from NETZSCH

When oil wells are initially opened for extraction after exploration, natural well pressure and generally enable oil, gas, and water to flow to the surface. Over time, as the well pressure declines, artificial lift methods must be applied to ensure resources reach the surface efficiently. Common artificial lift solutions include progressing cavity pumps (PCP), rod lifts, plunger lifts, gas lifts, hydraulic lifts, and electric submersible pumps (ESP), each suited to specific conditions.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems has successfully equipped an oil field with several progressing cavity pumps. We will show you the advantages of using progressing cavity pumps from NETZSCH for oil production.

Individual Consulting

Conventional Pumping Methods Prove to be Unreliable

NETZSCH, began a discussion with a oil producer that employed the gas lift method. The producer had just constructed a multi-pad well site having designed it in the gas lift artificial lift method.

In this system, high-pressure gas is injected into the wellbore, which forces the fluids to the surface. Each well then feeds the gas and fluids to a dedicated two-phase, horizontal separator, which divides a major portion of the gas from the well fluids. The gas is then directed back into the compressor to be re-injected into the well bore.

The liquids and residual gas (not separated in the initial phase) are sent to a vertical, two-phase separator for additional processing. The residual gas rises to the top of the separator and is fed back to the compressor. The fluids consisting of oil, water and some solids are then forced into the pumping system to be transported through pipelines to a central processing facility (CPF) where the oil is now separated from the water. The CPF is approximately 15 miles/ 25 Kms from the well site.

Conventional Technology

To date, the most common method to move the fluids to the CPF, has been the use of centrifugal pumps. However, in this case several issues are encountered when using centrifugal technology:

- Inability to handle the varying suction and discharge pressures and maintain consistent flow rates.

- Inability to handle the viscosity fluctuations and maintain consistent flow rates.

- Inability to handle solids that may be present in the fluids without extreme wear.

Centrifugal pumps are unable to maintain constant flows when suction pressures vary. This is also the case when discharge pressures fluctuate. To provide consistent flow rates, control valves and other instrumentation must be used to ensure the centrifugal pump is operating at its best efficiency point (BEP). If not, the flows drop off substantially reducing production.

Viscosity fluctuations are challenging for centrifugal pumps because flow output is affected. For instance, as viscosity increases the flow rate of a centrifugal pump will begin to rapidly decrease, and production rates are reduced.

The high speed impeller rotation of centrifugal pumps cannot handle solids or abrasives without accelerated wear. Because of the high speeds (3,600 rpm) solids and abrasives can cause rapid wear of the impellers, resulting in reduced production and high maintenance costs.

Progressing Cavity Pumps Resolve Key Issues

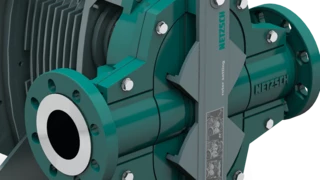

To overcome these issues, NETZSCH recommended NEMO® progressing cavity (PC) pump systems. These pumps are designed to handle variable suction and discharge pressures without compromising flow rates. Additionally, viscosity changes have minimal impact on the flow, ensuring steady production. With speeds controlled by VFDs, PC pumps meet pressure demands across a wide operating range.

The NEMO PC pump’s design, which includes a compression fit between the Rotorrotor,Rotors,rotorsrotor and stator, allows it to manage solids and abrasives with minimal wear. For this application, NETZSCH engineers recommended the SY model, 4 Pumps were installed to handle 30 barrels per day capacity across three wells.

Specialized Design for Enhanced Durability

The NEMO pump for this application was constructed with SAE 316 stainless steel and fitted with a NEMOLAST S459/S91 stator. Unique to NETZSCH, multiple universal joint options are available to handle demanding conditions. In this case, we chose the Z-type joint, a robust, double-seal pivot joint designed for high-flow, high-pressure operations. Oil-filled and hermetically sealed, the joint provides reliable operation with two independent seals compatible with both the lubricant and pumped fluid. Additionally, its balanced seal, or "equalizer," applies pressure on the lubrication oil in tandem with the seal pressure, accommodating suction pressures up to 1,000 psi (69 bar).

Installation and Continued Success

The complete pump setup, mounted on a heavy-duty I-beam skid and equipped with motor, gearbox, pressure gauges, sensors, and valves, was installed and anchored for stable operation. The start-up process was smooth, with engineers on-site to oversee commissioning. Since installation, the pumps have been running continuously, meeting production needs reliably.

The producer has expressed satisfaction with both the NETZSCH pumps' performance and the support provided by the NETZSCH team. The success of this deployment has led to additional units being ordered, with plans to incorporate NETZSCH pumps at future well sites for efficient transport of oil/water mixtures to central processing facilities.

SY Progressing Cavity Pump System

- Medium: Oil, gas, water mixture

- Temperature: 60 °C

- Pressure: 69 bar

- Flow rate: 4,77 m3/d