PUmp solutions for crude oil storage tank cleaning

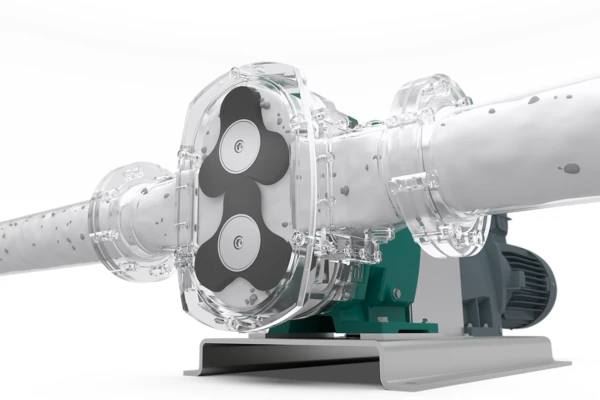

Enhance Efficiency in Tank Cleaning with Trolley Mounted TORNADO® Rotary Lobe Pumps

Discover how NETZSCH TORNADO® Rotary lobe pumps removes thick sludge settled in the storage tanks and enhance the effective storage capacity for crude oil in the tanks.

Crude oil tank farms in the oil and gas industry, serve as large storage facilities where the oil and its derivatives are stored before further processing or distribution. The most persistent issues in these farms are the accumulation of sludge at the bottom of storage tanks.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems has successfully provided a customized and engineered solution for sludge removal in the crude oil storage tanks. We are showing the advantages of using Rotary Lobe Pumps from the other pump technologies.

Individual Consulting

Thick sludge settles down the storage tanks

Typically, the thick crude oil sludge in storage tanks gradually gets settled down at the bottom and forms a thick layer that reduces the tanks effective storage capacity. Sludge tank cleaning was performed every 3-4 months which required tedious arrangements before the process and labour-intensive work during the process.

Existing pump technology and Challenges

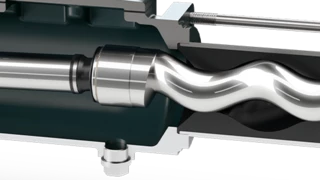

The cleaning process was carried out with a combination of centrifugal pumps and progressive cavity pumps at the tank farms.

The centrifugal pumps take out the thin sludge from the surface level. As the cleaning progresses, a thicker and more viscous sludge starts to set in where manual intervention became necessary.

Workers add chemicals, and scrape the sludge manually, and transfers it to sludge pits present in the corner of the tanks. Progressive cavity pumps pump out this thick sludge out of the tanks.

Trolley mounted pumps are used for sludge tank cleaning because the pump had to be moved around to different tanks during their cleaning cycles. Movement of the long progressive cavity pumps in open roads was difficult and caused handling difficulties.

After continuous experiences of reduced flow rate due to the high viscosity sludge and frequent stator failure due to dry running, low negative suction capabilities of progressive cavity pump, high operational costs and safety issues, the client sought for alternative solutions that is more efficient, time saving and space saving.

Rotary lobe pump addressed several challenges effectively

Its compact size reduced the equipment footprint, making it easier to move around the tanks with trolley mounted pumps.

Handles thick sludges and large compressible solids like lumps without any issue and without the need for manual intervention. This reduces frequent breakdowns and improve operational reliability.

These pumps were supplied with control panels, that automated the cleaning operation of significant parts, reducing the dependency on manual labour.

Its negative lift capability and ability to handle intermediate dry running made it robust from failures.

The operational costs and safety issues associated with manual cleaning and pump maintenance were brought under control.

NETZSCH is committed to offering innovative, industry-specific solutions that translate to substantial benefits for customers

Whether industrial, chemical, or food, you can buy the appropriate rotary lobe pump design from NETZSCH, your global partner in handling complex media. Together with you, we will find the model optimized for you and your application.

TORNADO® Rotary Lobe Pumps

- Medium: Crude Oil Sludge

- Throughput volume: 15 m³/h

- Rotation speed: 213 rpm

- Pressure: 4.6 bar

- Viscosity: 18000 cP

- Temperature: 40 °C